Why the STACKED RJ45 OVER 2 USB TYPE Connector Is the Smart Choice for Modern Designs?

The STACKED RJ45 OVER 2 USB TYPE Connector http://www.wahsondg.com is becoming the smart choice for modern electronic designs. By integrating high-speed networking with versatile USB connectivity, the STACKED RJ45 OVER 2 USB TYPE Connector offers space-saving efficiency and reliable performance. For engineers and product developers, adopting the STACKED RJ45 OVER 2 USB TYPE Connector means streamlined layouts, enhanced functionality, and future-ready compatibility in compact devices.

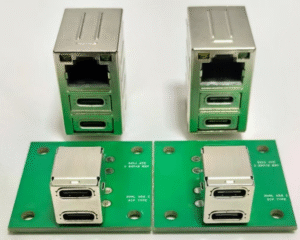

Space-Saving Design for Modern PCBs

One of the greatest advantages of the STACKED RJ45 OVER 2 USB TYPE Connector is its ability to combine networking and USB connectivity in a single, compact footprint. By stacking RJ45 ports above dual USB connectors, designers can save valuable PCB space, reduce clutter, and achieve cleaner layouts. This integration is especially beneficial in applications such as industrial controllers, communication equipment, and compact computing devices where board real estate is limited.

Enhanced Functionality and Versatility

Modern designs often require both Ethernet and USB interfaces. Traditionally, separate connectors would consume more space and complicate wiring. The STACKED RJ45 OVER 2 USB TYPE Connector solves this challenge by integrating two essential functions into one component. Engineers can now deliver high-speed data transfer, reliable networking, and versatile peripheral connectivity in a streamlined design.

Reliability and Performance

As a professional connector manufacturer, we understand that performance and durability are non-negotiable. The STACKED RJ45 OVER 2 USB TYPE Connector is engineered with precision contacts, robust housing, and strict quality control to ensure long-term reliability. Whether used in servers, routers, or embedded systems, this connector provides stable signal transmission and mechanical strength, meeting the rigorous demands of modern electronics.

Applications Across Industries

The versatility of the STACKED RJ45 OVER 2 USB TYPE Connector makes it suitable for a wide range of applications:

- Networking equipment: Routers, switches, and gateways benefit from compact designs with dual functionality.

- Industrial automation: Controllers and monitoring systems require both Ethernet connectivity and USB interfaces for sensors and peripherals.

- Consumer electronics: Compact PCs, smart devices, and multimedia systems gain space efficiency and enhanced usability.

Why Choose Us as Your Connector Manufacturer?

As a dedicated connector manufacturer, we provide not only high-quality products but also tailored solutions to meet customer needs. Our expertise in stacked connectors, RJ45, and USB integration ensures that every product is designed for performance, compliance, and ease of use. By choosing us, customers benefit from:

- Direct factory supply with competitive pricing

- Strict quality assurance and international certifications

- Customization options for different layouts and specifications

- Technical support for modern PCB design challenges

Conclusion

The STACKED RJ45 OVER 2 USB TYPE Connector is more than just a component—it is a strategic choice for engineers seeking smarter, space-saving, and multifunctional designs. With its compact footprint, reliable performance, and wide application range, it represents the future of connector solutions in modern electronics. Partnering with a trusted connector manufacturer ensures that your designs remain competitive, efficient, and ready for tomorrow’s innovations.

The STACKED RJ45 OVER 2 USB TYPE Connector is the space-saving solution for modern PCB designs, combining efficient layout with reliable performance. As a professional connector manufacturer http://www.wahsondg.com, we deliver high-quality stacked RJ45 and USB solutions that optimize board space, enhance functionality, and meet the demands of next-generation electronic products.

Ready to Source?

Whether you’re prototyping or scaling up production, the STACKED RJ45 OVER 2 USB TYPE connector is a smart investment in performance and efficiency. Contact us today to explore datasheets, MOQ options, and lead times tailored to your region.